Material Processors

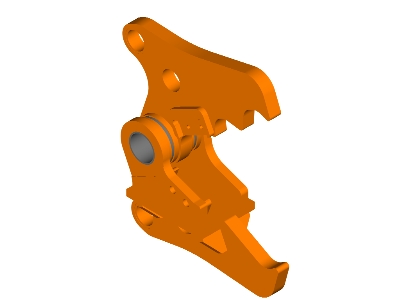

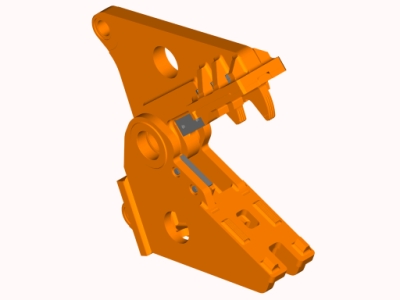

Concrete Pulverizers | Demolition Shears | Concrete Crackers

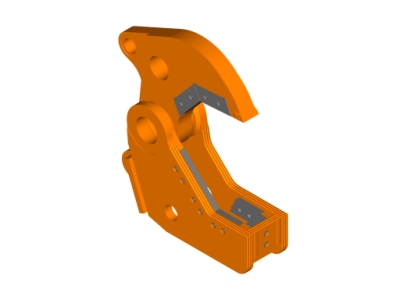

NPK's Material Processors are an efficient solution for concrete, steel and rebar processing; building and bridge demolition; and recycling.

Maximum productivity with rugged design for extended life

Interchangeable jaws provide superior results in demolition, concrete processing and scrap recycling. Manufactured from high-strength, abrasion-resistant steel; reinforced shield protects cylinder rods. Full 360° hydraulic rotation provides an effective angle of attack for any job, wherever the location.

Cylinder design improves crushing/cutting power to handle the toughest jobs

NPK’s exclusive integral hydraulic intensifier system boosts power and reduces cycle time, thus increasing the power-to-weight ratio. The powerful crushing forces increase when jaws meet resistance as the intensifier converts flow to pressure. Competitive cylinder systems need larger cylinders to equal the force developed by the more compact NPK intensifier system.

Cost effective in regards to both equipment and transportation

Far more economical than buying three different demolition attachments for three different applications. On-the-job processing reduces material volume, which cuts down the number of trips required to haul material away.

The NPK advantage in parts and service

Over 350 NPK distributor outlets are professionally staffed and conveniently located to serve your needs. Just one of the many reasons that have made NPK the leader in excavator-mounted hydraulic attachments.

NPK dedicated mounting kits enable material processors to be mounted as excavator attachments for carriers within the recommended weight range for each model. See the Attachment Wizard to determine which NPK hydraulic attachments are compatible with your carrier.

Potential applications include:

- Construction and Demolition (C&D) recycling / sorting

- Concrete recycling

- Commercial demolition

- Separating concrete from rebar

- Concrete cracking

- Cutting rebar, pipe, steel, and other scrap metal

Visit and subscribe to NPK's YouTube channel for videos of material processors in action!

Visit NPK's photo website for searchable material processor photo galleries!

Visit the Material Processor Publications page for sales brochures, operation & maintenance manuals, and service bulletins.

Visit each material processor model page below for additional images and specifications. If you require a booster service manual or would like a hard copy of the operation and maintenance manual, please contact the Sales department at 440-232-7900 or by email at sales@npkce.com.

On-site versatility is optimized by the availability of interchangeable jaws:

| Image | Model | Recommended Carrier Weight | Jaw Set Type | |

|---|---|---|---|---|

|

M20G | 40,000 - 50,000 lb | concrete pulverizer |

|

|

M20K | 40,000 - 50,000 lb | demolition shear |

|

|

M20S | 40,000 - 50,000 lb | concrete cracker |

|

|

M28G | 50,000 - 80,000 lb | concrete pulverizer |

|

|

M28K | 50,000 - 80,000 lb | demolition shear |

|

|

M28S | 50,000 - 80,000 lb | concrete cracker |

|

|

M35G | 60,000 - 80,000 lb | concrete pulverizer |

|

|

M35K | 60,000 - 80,000 lb | demolition shear |

|

|

M35S | 60,000 - 80,000 lb | concrete cracker |

|

|

M38G | 66,000 - 110,000 lb | concrete pulverizer |

|

|

M38K | 66,000 - 110,000 lb | demolition shear |

|

|

M38S | 66,000 - 110,000 lb | concrete cracker |

|

GOOGLE TRANSLATOR

GOOGLE TRANSLATOR