Tools for Hydraulic Hammers

A hydraulic hammer converts hydraulic power to kinetic energy. The kinetic energy is delivered by the hammer piston to the tool as an impact force. Choose and use the tool that is most suited for the work. Using a tool not suited for the work not only reduces the working efficiency but may cause chipping, deformation, or other damage to the tool.

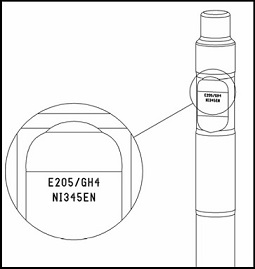

NPK tools can be identified by the numbers found stamped in the retaining pin slot.

Consult the NPK Hydraulic Hammer Tool Manual for more detailed information about impact energy, tool lubrication, correct use, breakage, and warranty information. Visit the Hammer Accessories Publications page for sales brochures and manuals.

Standard Tools

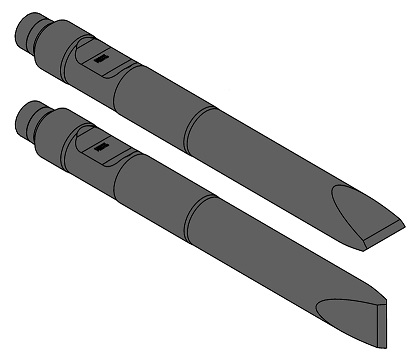

Chisel (FX) or (FY)

The chisel is the most commonly used demolition tool. Standard chisels have a cross-cut configuration. Cross-cut tools cut at a right angle to the stick and boom of the carrier. In-line chisels are available upon request.

Applications:

- controlled breakage of concrete

- layered sedimentary rock

- trenching

- oversize

- cutting casting gates

- general demolition

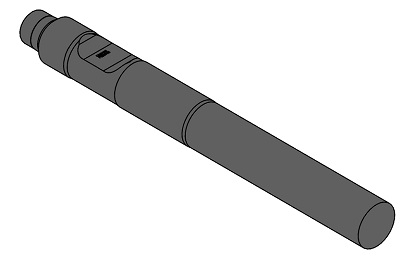

Moil Point (P)

The shape of this tool allows dust and chips to escape on all sides and creates an exceptional penetration rate.

Applications:

- soft material

- breaking concrete structures - columns, etc.

- highway construction

- general demolition

Blunt Tool (E)

The large, flat surface at the tip of this tool ensures stability while creating exceptional shattering force.

Applications:

- concrete slab, bridge decking

- breaking oversize

- slag removal

Optional Tools

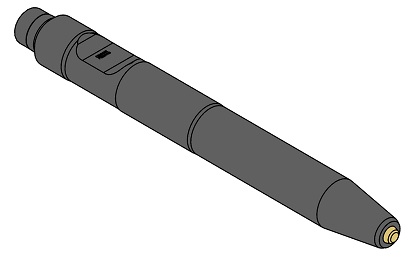

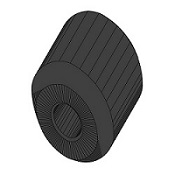

Core Tool (PC)

Due to its unique design, NPK's core tool increases productivity and far exceeds normal tool life. It's patented carbide steel core minimizes wear and breakage. Core tools are available for hydraulic hammers size PH2 - GH50 (and equivalent discontinued hammers).

Applications:

- hard rock

- general demolition

This innovative tool contains a carbide steel core delivering maximum impact and penetration upon contact. The point of the tool remains sharp because the steel surrounding the core wears at a faster rate. Consequently, efficiency is maximized as replacement costs are minimized.

Traditional tools can experience tip temperatures of over 1000 ℉ on typical jobs. The high temperatures alter the tool's hardness as it cools, causing mushrooming or embrittlement. NPK's core tools experience less temperature change and minimum hardness variations.

Accessory Tools

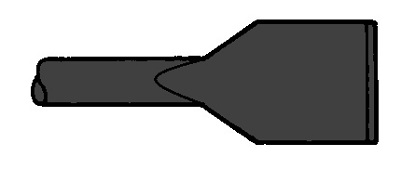

Frost Cutter Tool

This tool is available in both a cross-cut and in-line configuration. Cross-cut tools cut at a right angle to the stick and boom of the carrier.

Applications:

- frost cutting

- edge of trenching

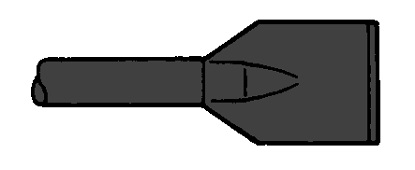

Asphalt Cutter Tool

Designed to facilitate complete and efficient removal of asphalt for special applications.

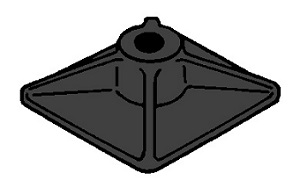

Adapter Tool Assemblies

Adapter tools are paired with tamper plates or post / pipe drivers.Tamper plate assemblies are available for hydraulic hammers size PH07 - PH4 (and equivalent discontinued NPK hammers). Plates range from 6" x 6" to 16" x 16" depending on hammer size.

Post / pipe driver assemblies are available for hydraulic hammers size PH1 - PH4 (and equivalent discontinued NPK hammers).

Tamper Plate Applications:

- soil compaction

- driving sheeting

Post / Pipe Driver Applications:

- driving guard rails

- driving fence posts

GOOGLE TRANSLATOR

GOOGLE TRANSLATOR